What does a golf course and Geofoam have in common? I have to level with you, that Geofoam has been used for so many things it’s hard to be straight on all of its uses. Trump Golf Links at Ferry Point is an excellent example of how Geofoam can even find its way onto (or under) a golf facility. Although our President has his moniker on the project, it was designed by Jack Niklaus.

In 2009 Poly Molding was a critical part of the Bronx links’ design of the entire 18-hole course. By underlying the course with 20,000 cubic yards with Geofoam to create berms, valleys, twists and turns of hills throughout the course, it took 200 truckloads to do so. Sounds like a hole-in-one for Geofoam. Can you say Whoop, Whoop?

In an article featured in Inc. magazine in 2015, the writer Will Yakowicz lauded Poly Molding as a critical vendor to the project. The Inc. article goes on to describe all the projects in which Poly Molding participated in the Tri-State area.

In keeping with the boasting tradition of its owner, this website gives a glimpse of the course:

Recognized as one of the best public golf courses anywhere in the world!

“Trump Golf Links at Ferry Point has been designed to the absolute highest-level standard and quality by the famed Jack Nicklaus. You will experience not only an incredible course, but five-star facilities, world-class hospitality and amazing views everywhere you turn. The rolling mounds of golden fescue bordering 7,407 yards of pristine tees, fairways and greens, creates a golf experience unlike any other, let alone being located only 10 minutes from Manhattan. This course has received extraordinary reviews from architects, writers, and other industry professionals. This spectacular property will soon host the most significant and prestigious events in golf.” – Trump Ferry Point

But don’t think that this is a one-time occurrence for EPS foam. In the sport of golf, it is pretty rare but not impossible that a player hits a hole-in-one. But once was not enough for Geofoam.

Although Poly Molding was not involved with this project in Georgia in 2012, the Jack Niklaus Country Club of the South utilized Geofoam to solve an 18th Hole viewing area. An open-air terrace nearly a 3000 square feet expanse needed shoring, but there was no access for trucks delivering fill. Should the architects did go with fill dirt, the trucks’ only path was to destroy a good portion of the landscaping AND the 18th hole — Geofoam to the rescue.

“Geofoam fill gave us the strength we needed and eliminated the lateral load on the downslope,” Rex said. “Using lightweight geofoam blocks made installation much easier and the landscape remained unscathed.” – Stanley D. Lindsey and Assoc.

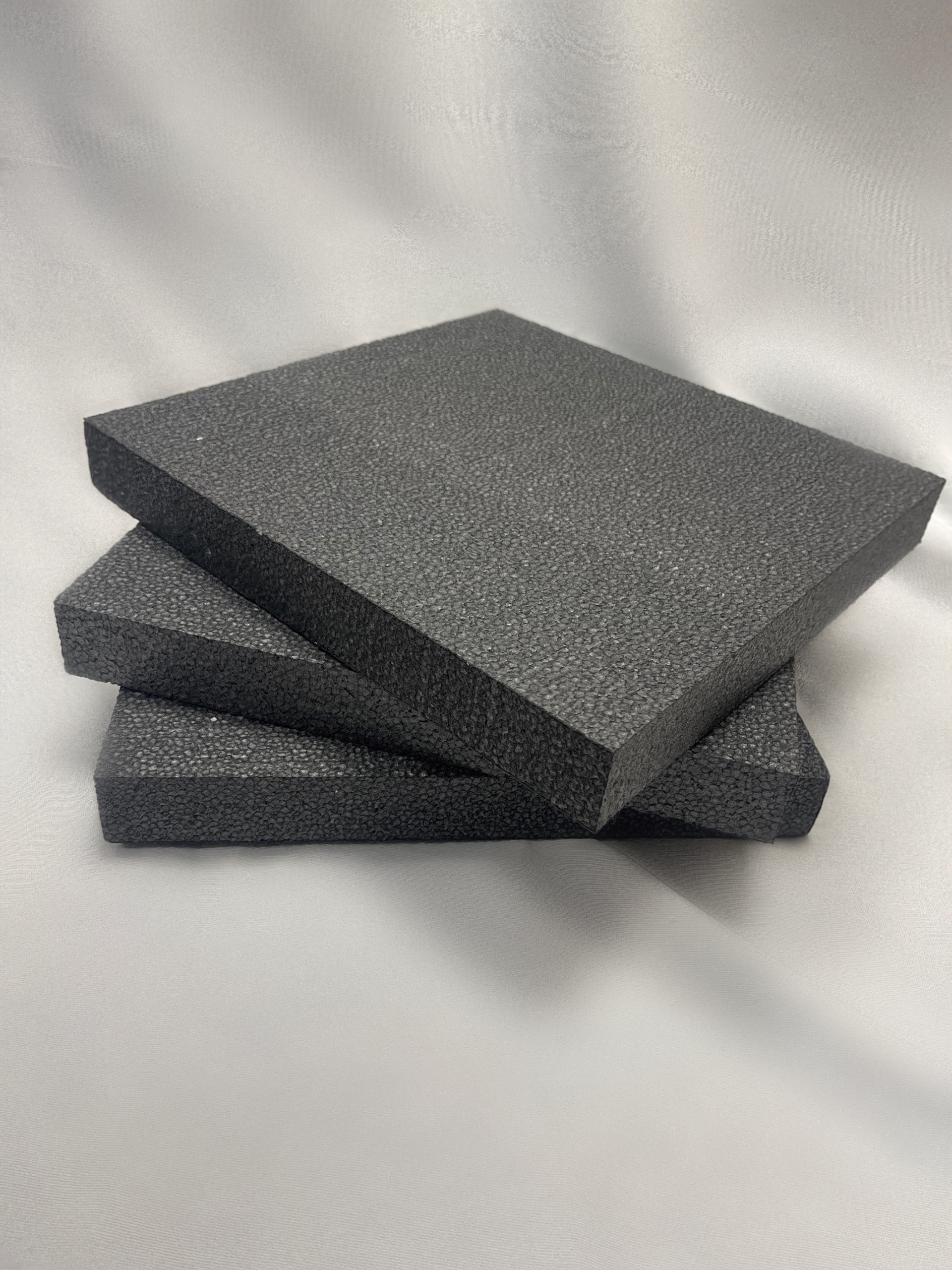

There are other golf course facilities where Geofoam was used to create the rolling hill, valleys, peaks, and plummets. The ease in which Geofoam can be shaped to just about any purpose and transporting it to hole number 7 is not a problem as a 4 X 8-foot block weighs slightly less than 100 pounds.

As a soil substitute, Geofoam solves so many problems for heavy construction (embankments, pilings) residential construction (insulation, block for exterior shell), and now we’ve discovered yet another use for this fantastic product. Another hole-in-one for the Geofoam Champion.

So maybe you can practice your hole-in-0ne drives, chipping or putting on a floating green someday soon. Due to Geofoam’s composition, it makes for excellent flotation. Just know that Geofoam is probably on the job.