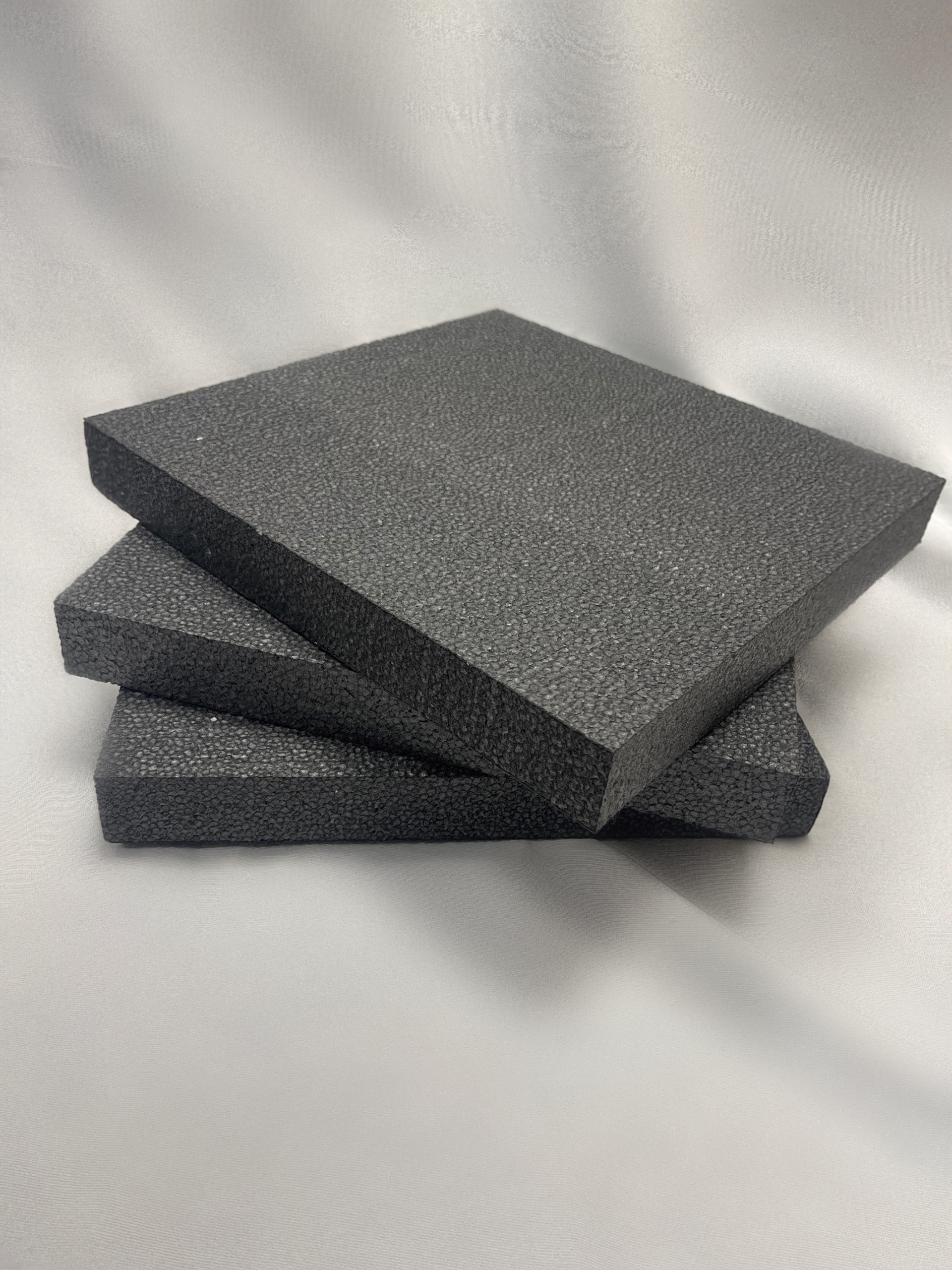

The construction industry is ever-changing and as the world embraces a greener future, the construction industry becomes more sustainable as well. Their answer to this? EPS Geofoam. Besides being an eco-friendly alternative to traditional building materials, EPS geofoam boasts several benefits. EPS Geofoam is affordable, is 100 times lighter than soil, and has fewer manpower needs. All while being kind to the earth. To find out the exact ways in which EPS geofoam is helping instead of hurting our environment, continue reading.

Doesn’t Contribute to Global Warming

Hydrochlorofluorocarbons, or HCFC in short, is an extremely harmful greenhouse gas as it depletes the stratospheric ozone, which is the earth’s layer that protects us from the sun’s UV rays. The compound also heats up the earth’s lower atmosphere, thus altering the global climate in the long run. EPS Geofoam is HCFC-free, making it a guilt-free choice for the building of both commercial and industrial infrastructure.

No Emission of Toxic Chemicals

As EPS geofoam contains zero formaldehyde, it will not emit toxic vapors. Formaldehydes not only cause catastrophic effects on the environment but also on us humans. For the environment, formaldehyde is particularly damaging to aquatic life in our lakes, rivers, and oceans. For humans, toxic vapors can irritate our skin, eyes, throat, nose, and even lungs, leading to breathing difficulties. As such, the use of EPS geofoam can reduce and prevent potential health conditions from occurring over time.

Reduces Garbage

Another great thing about EPS geofoam is that it is 100% recyclable, which means less trash would end up in landfills and incineration plants. This creates a domino effect as more natural resources would be conserved, energy consumption is decreased, and pollution would be significantly reduced, as well as greenhouse gas emissions. All these contribute to a cleaner and safer earth that’s better to live in. Less waste also positively impacts our health, as we breathe in fewer toxins.

Saves Energy

Being an efficient thermal insulator, EPS geofoam can prevent heat gain or loss without the use of energy. Its low density also means that it can optimize insulation and circulation of heat better. Therefore, energy consumption will be lowered, which reduces the number of toxic pollutants released from power plants. By opting for EPS geofoam in construction activities, we can reduce our carbon footprints and not rely too heavily on power plants or imported energy.

Seeking a Geofoam Manufacturer in New Jersey?

Well, look no further as Poly Molding has exactly what you’re looking for. As the only EPS geofoam manufacturer in New Jersey, we’re an incredible local resource and have the capabilities to ship our products wherever your project is located. We pride ourselves on providing only the highest quality of Expanded Polystyrene products and have supplied many clients across multiple industries. Our EPS geofoam is used for a wide range of structural projects, from commercial and industrial buildings to landscaping. If you have any queries, we have an experienced team of experts who are always ready to answer your questions.

Contact us at (800) 229-7161 or (973) 835-7161.