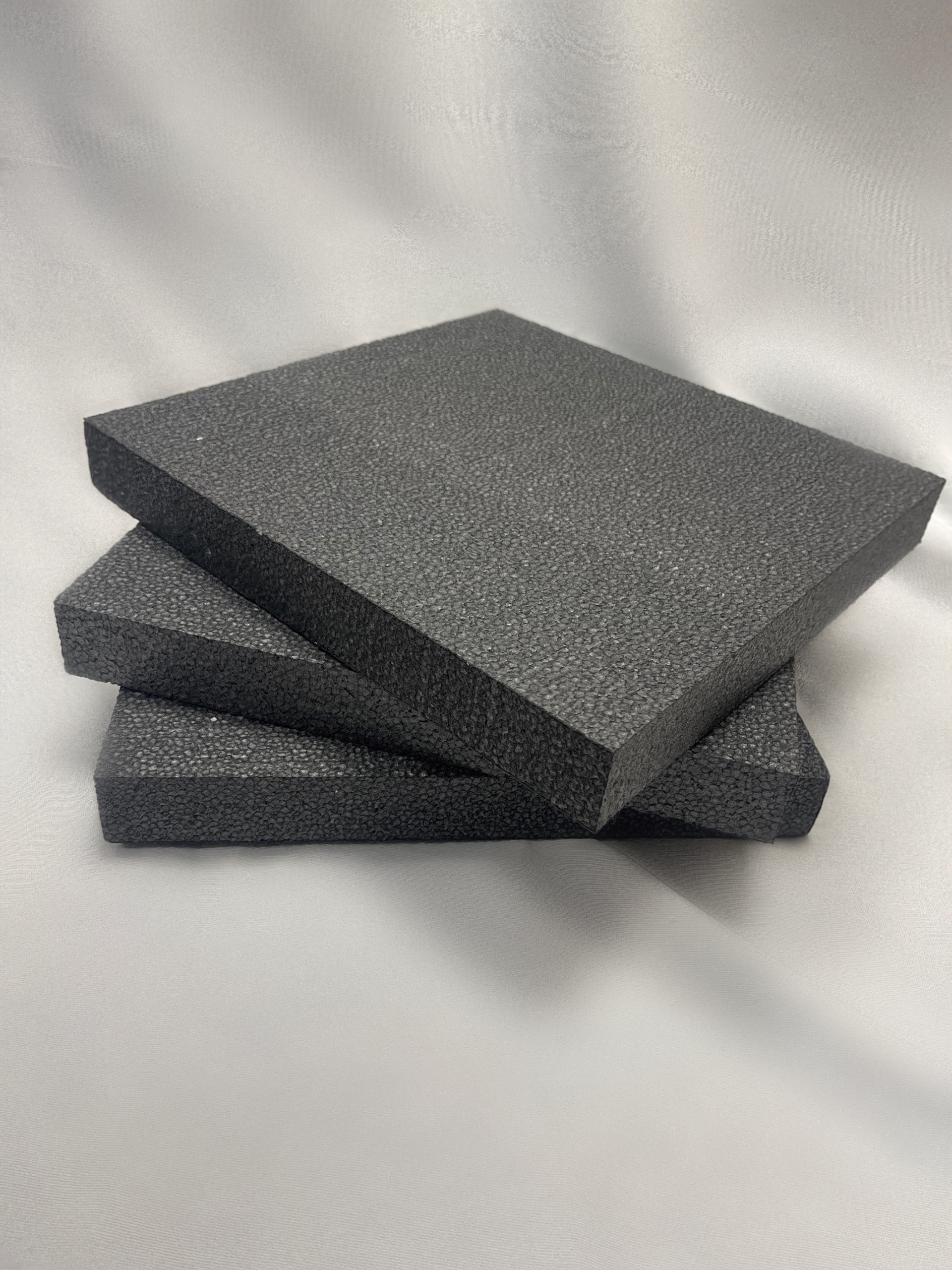

EPS Geofoam has emerged as the shining star in the modern construction industry. Its affordable pricing and sustainable contribution are just some of the advantages that give an edge to EPS geofoam as compared to more traditional fill materials. However, the most significant factor why many construction firms are opting for geofoam is probably the convenience of using it. In this article, we’ll discuss how geofoam saves time and the ways it speeds up construction projects.

Flexibility

Unlike traditional fill solutions, geofoam is customizable and can be easily shaped to suit the geometries of the structure. This means that there will be no need for last-minute trimmings, thus accelerating the construction process. In addition, geofoam can withstand harsh conditions, and its thermodynamic properties enable it to insulate heat without causing damage to the infrastructure. Considering these factors, it’s no wonder that EPS Geofoam is the answer to stable structures.

Reduce Labor

A significant benefit of using geofoam is that it’s extremely lightweight. Geofoam weighs 100 times lighter than soil and 30 times lighter than traditional fill materials. This makes it easy to maneuver around and does not require a large amount of manpower, saving time and labor costs. Workers are also not prone to potential injuries since they’re able to lift the material with ease, which improves their physical well-being as a whole and allows them to work quickly.

Easy to Install

Traditional fill materials such as soil and rocks, to name a few, are notoriously difficult to transport due to their heavy weight. As such, transporting such materials can be time-consuming and costly. Since Expanded Polystyrene geofoam is comparably lighter and simple to install, it can be stored in fewer truckloads and transported at a faster rate. Once geofoam is on-site, there’s no need for pre-cuts or field trimmings as it is a fully engineered product and can be immediately placed into various foundations.

Soil Remediation

Building on soft or poor soil is every construction team’s nightmare. Challenges such as slope instability and excessive settlement can occur during or after the construction process, which undoubtedly would slow down the project. However, it’s vital to establish a solid foundation before any structure is set up.

Considering geofoam’s light weight, it can support heavy loads without providing additional pressure on the underlying soil. This can’t be said for traditional fill solutions like soil as it is not only dense but also has high compressibility, which increases the chances for mishaps to occur.

Go for Poly Molding

Even though Poly Molding is based in New Jersey, we provide geofoam throughout the Northeast coast of the United States, from New York to Pennsylvania, and beyond. You’ll find that despite their affordable price, our geofoam products do not compromise on quality and function. We regularly test our Expanded Polystyrene products to ensure the utmost quality and that they can last for a long period of time. If you have any queries, our experts are always glad to offer more information.

You can contact us at (877) 537-7199 or (973) 835-7161.