If you are looking to incorporate EPS geofoam into your project but are unfamiliar with it, here are some questions you might have.

What Is EPS Geofoam?

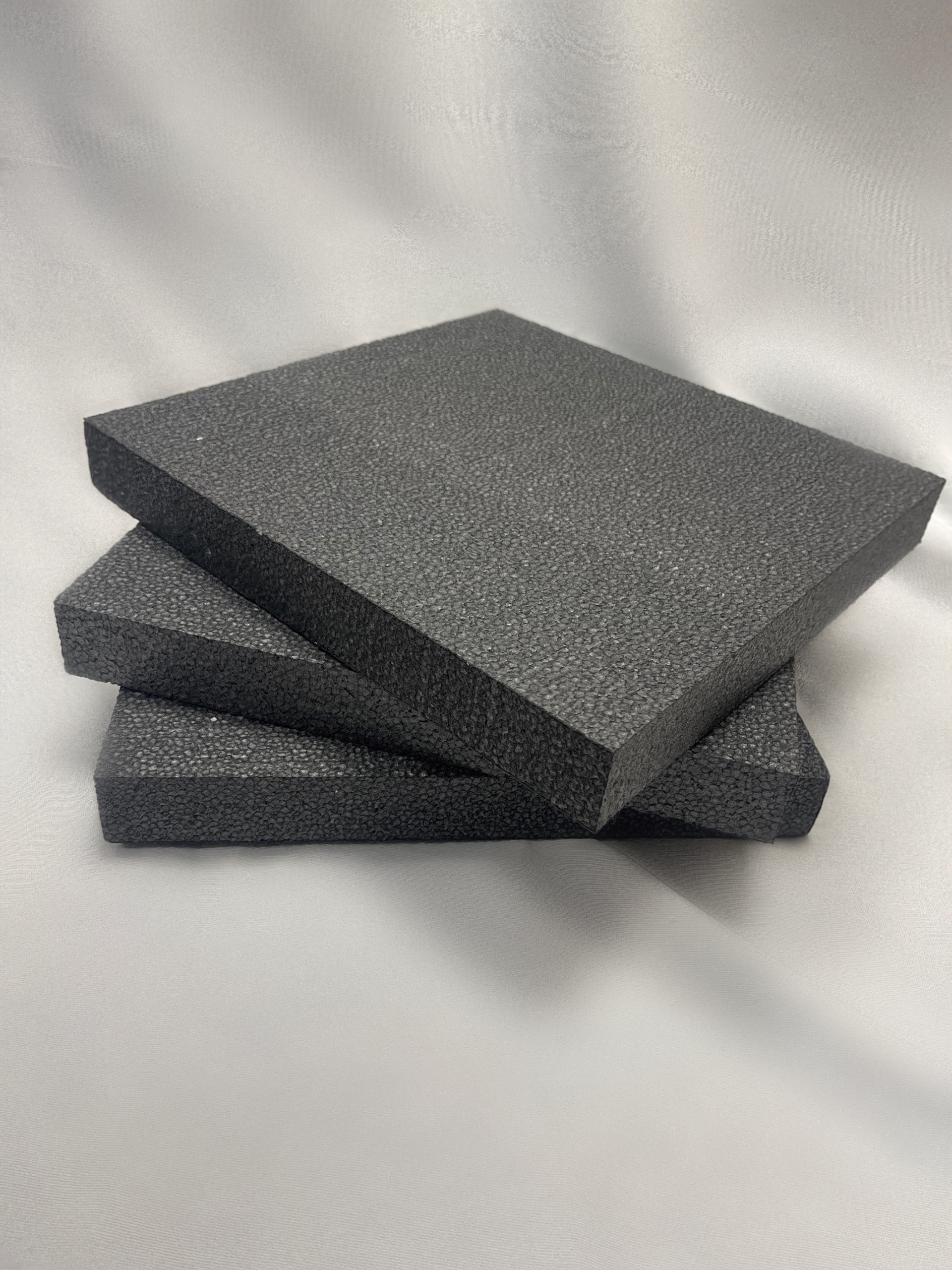

EPS geofoam is a lightweight yet durable building material made of expanded polystyrene via a process known as polymerization. Its closed-cell structure makes it resistant to water and decomposition, with virtually no need for maintenance. It also has a 98% to 99% air by volume composition, making it ideal for thermal insulation. Overall, EPS geofoam is extremely versatile and can work in an extensive range of construction applications.

What Kind of Construction Method Does EPS Geofoam Use?

Unlike traditional construction materials, EPS geofoam blocks are 1% the weight of soil and less than 10% the weight of other lightweight fills. Their lightweight properties help in the reduction of settlement and enhancing stability against bearing and slope failures. Supporting retaining or foundation walls and bridge abutments using EPS geofoam blocks reduces lateral stress and weight on the structure significantly. Furthermore, the high compressive strength of EPS geofoam (up to 60 psi) ensures improved durability during the structure’s lifetime. EPS geofoam is considerably easier to handle and install; projects generally take less time and effort as compared to others utilizing traditional construction methods.

What Is the Installation Process Like?

EPS geofoam can be carried by hand without the use of heavy machinery or masterful techniques. Given that the blocks can be manufactured to size, there is little or no need for retrofitting. They can be easily molded on-site in the case of modifications or last-minute adjustments. Due to its easy handling and installation, using EPS geofoam blocks may shave weeks off your schedule, allowing you to complete the project on time. You can also save on the costs of extra manpower and transportation. Safety-wise, less manpower and the lack of heavy equipment provide fewer opportunities for workplace injuries and other avoidable accidents.

Can EPS Geofoam Carry a Lot of Weight?

The ASTM C578 compression standard for Type 1 EPS geofoam is based on 10% deformation, requiring tensile strength of 1,400 pounds/square foot. One square inch of EPS geofoam can support 10 pounds even while compressed to 90% of its original thickness. One pound of EPS geofoam can sustain 3.5 pounds per square inch if you need to keep 1% or less deformation. Its durability and resistance to external damage are the results of its high compressive strength.

What Is the Environmental Impact of Geofoam?

EPS geofoam is an extremely eco-friendly building material. Potentially hazardous greenhouse gases are neither utilized during the manufacturing process nor released by the product. It does not contain formaldehyde, dyes, chlorofluorocarbons (CFCs), or hydrochlorofluorocarbons (HCFCs). EPS geofoam products themselves are 100% recyclable and may incorporate up to 10% of recycled materials. The lightweight properties of EPS geofoam enable less fuel consumption and a shorter construction time, decreasing its environmental impact. It is also an excellent thermal insulator, helping to reduce overall energy consumption in the long term.

Meet All Your Insulation Needs with Poly Molding

Poly Molding is New Jersey’s sole geofoam/EPS manufacturer and specializes in the supply and implementation of geofoam products across different sectors and industries. Contact our team of experienced professionals if you are interested to find out more about geofoam and how to incorporate it into your project.