Insulation is key in the construction of any residential or commercial structure. Choosing the best type of insulation for your project depends on several factors, like budget, environmental impact, and R-value, the measure of an insulation material’s resistance to heat flow. It is hence important to be knowledgeable about the different types that can be used. Here are a few to take note of:

Concrete Blocks

Concrete blocks are frequently used in the construction of walls and foundations in new projects of renovation works, although little thermal resistance is provided. They are highly resistant to mold, mildew, pests, and fire, and emit little volatile organic compounds (VOCs). However, concrete blocks alone are inadequate and often require moisture barriers or additional insulation, so as to yield a higher R-value.

Insulated Concrete Forms (ICFs)

Insulated concrete forms are permanent forms filled with five to six inches of reinforced concrete. This allows for two built-in layers of insulation made of polypropylene plastic. Stackable and interlinking, these are often used to build walls, ceilings, and foundations. Although ICFs have high thermal resistance, resistance to mold, moisture, and fire, and high energy efficiency levels, they can be costly due to the special skillset needed.

Reflective Systems

Reflective systems are commonly utilized in the insulation of unfinished walls, floors, and ceilings. They function by interrupting radiant heat, such as heat radiating from the bottom of a roof, rather than reducing conductive heat transfer. A radiant barrier, in most cases, inhibits heat transmission through the integration of highly reflective aluminum foils. Their effectiveness can be affected by cooler climates and the build-up of dirt or debris.

Rigid Fiber Insulation

Typical made from fiberglass or mineral wool, rigid fiber insulation boards are primarily used for thermal insulation of air ducts for industrial heating, air conditioning, electricity, and process equipment. They are resistant to mold and high temperatures, are non-combustible, and do not emit greenhouse gases. However, fiberglass fibers may irritate eyes, skin, and lungs, and applications of the boards are generally limited in usage.

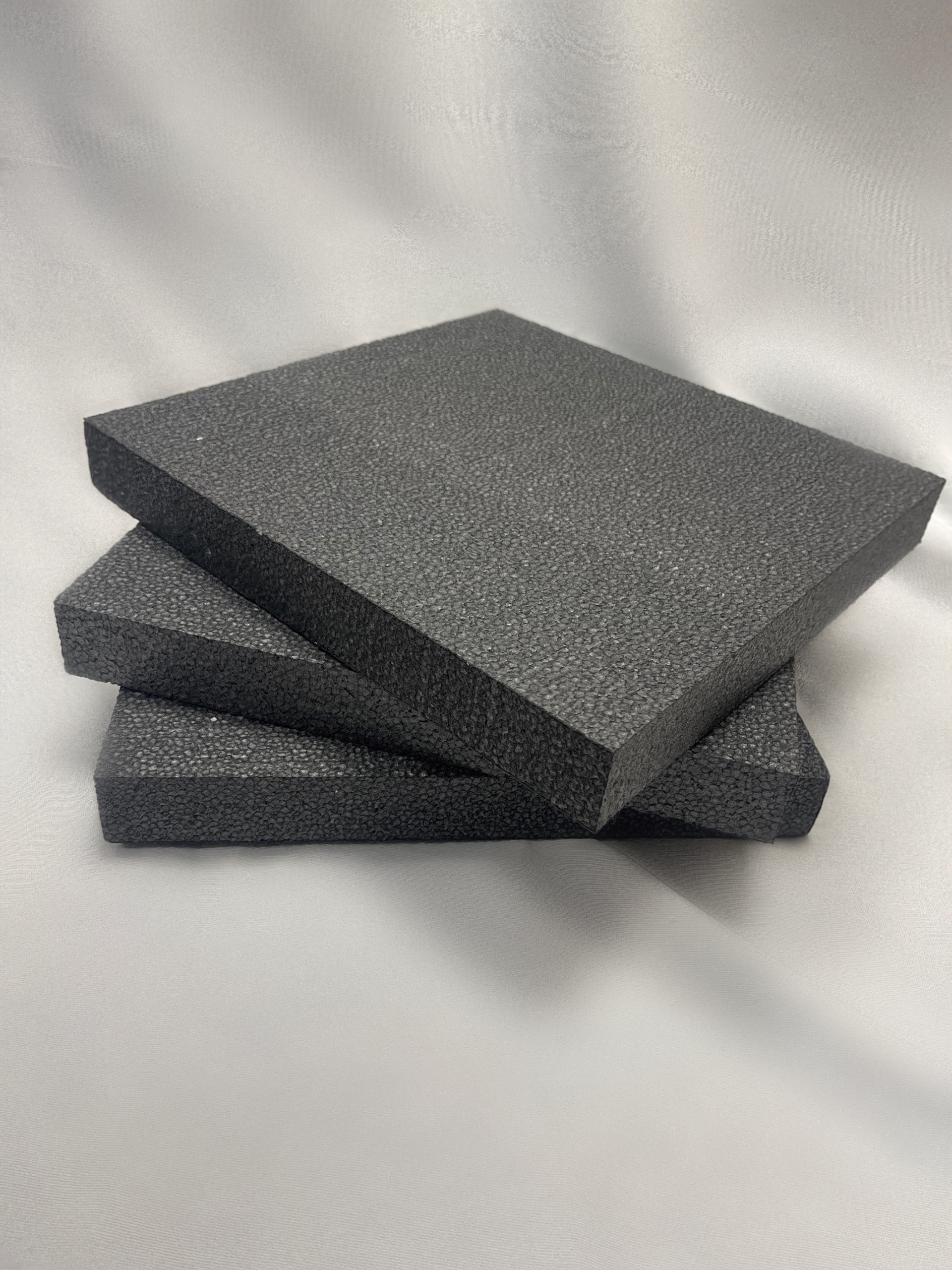

EPS Geofoam

EPS geofoam is composed of expanded polystyrene (EPS) particles that are formed into big, lightweight blocks of varying sizes. Despite being lightweight in composition, geofoam is strong, durable, and can be utilized in a variety of building and construction industries due to its capacity to ensure stability in unstable soil conditions. EPS geofoam is easily installed in most climate conditions, is affordably priced, and is resistant to decomposition or decay. It is also environmentally friendly, being free of hazardous HFCFs or formaldehyde, and is 100% recyclable.

Poly Molding specializes in the supply of high-quality geofoam products that are utilized in a wide range of industries and sectors and can advise you on the best way to incorporate this eco-friendly, lightweight, and inexpensive insulation material into your project. One such product is POLY RITE, a laminated insulation board with an EPS core that offers good protection and durability.

Meet All Your Insulation Needs with Poly Molding

As New Jersey’s only geofoam/EPS manufacturer, Poly Molding specializes in geofoam for construction in both the public and private sectors. Our dependable and cost-effective EPS insulation can be utilized in the majority of roofing systems. Contact us if you would like to find out more about geofoam and the other polystyrene products we offer.