Expanded Polystyrene or EPS Geofoam has become one of the most sustainable construction material available.

Expanded Polystyrene or EPS Geofoam is strong, lightweight, water resistant with excellent insulation properties. Expanded Polystyrene (EPS) Geofoam is widely used in construction projects ranging from bridges, buildings, roadways, stadiums and Green Roofs.

EPS geofoam is crucial for foundation fill due to its lightweight yet strong properties. It significantly reduces the load on underlying soil, preventing settlement issues and enhancing the stability of the structure. Additionally, its ease of handling and installation speeds up construction timelines, making EPS geofoam an efficient and reliable choice for modern foundation solutions.

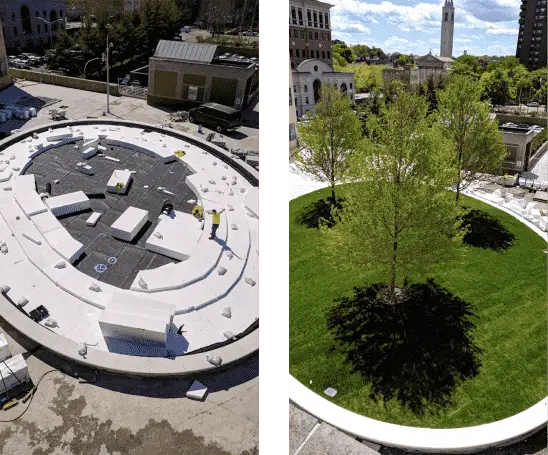

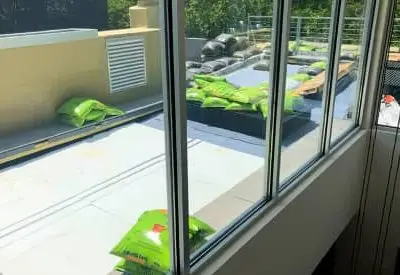

Creating topography with EPS geofoam is an efficient way to avoid putting excessive strain on underlying structures and services. One practical application of this technique is in the construction of roof gardens for urban buildings

EPS geofoam significantly reduces lateral stresses on bridge abutment walls, bridge foundations, and other retaining structures. In addition to its exceptional compressive resistance, EPS geofoam is an ideal solution for construction projects requiring reliable support and stress reduction.

EPS geofoam is an excellent solution for constructing new roads, especially when they need to be built over soft or loose soils that cannot support additional loads.

Using EPS geofoam for landscaping offers unparalleled benefits. The ability to cut and shape EPS geofoam on-site enables you to create any contour and undulation in your landscaping profile, ensuring a perfect fit for your design vision

EPS Geofoam is the ideal solution for avoiding excessive pressure on underlying soils and neighboring structures. By replacing compressible soils or heavier roadside fill materials with EPS Geofoam, you can ensure better stability and longevity for your projects.

Expanded Polystyrene (EPS) Geofoam is a lightweight, yet strong material widely used in geotechnical applications. Ideal for construction on soft ground, EPS geofoam serves as lightweight fill, slope stabilization, retaining wall or abutment backfill, sub-grade insulation, and foundation insulation for roadways and runways.

EPS Geofoam’s multifunctionality makes it a top choice for diverse construction needs. From foundations to road embankments, engineers, architects, and builders can leverage EPS geofoam to meet crucial geosynthetic functionalities. By selecting the optimal product combination, professionals can efficiently achieve their project objectives with EPS geofoam.

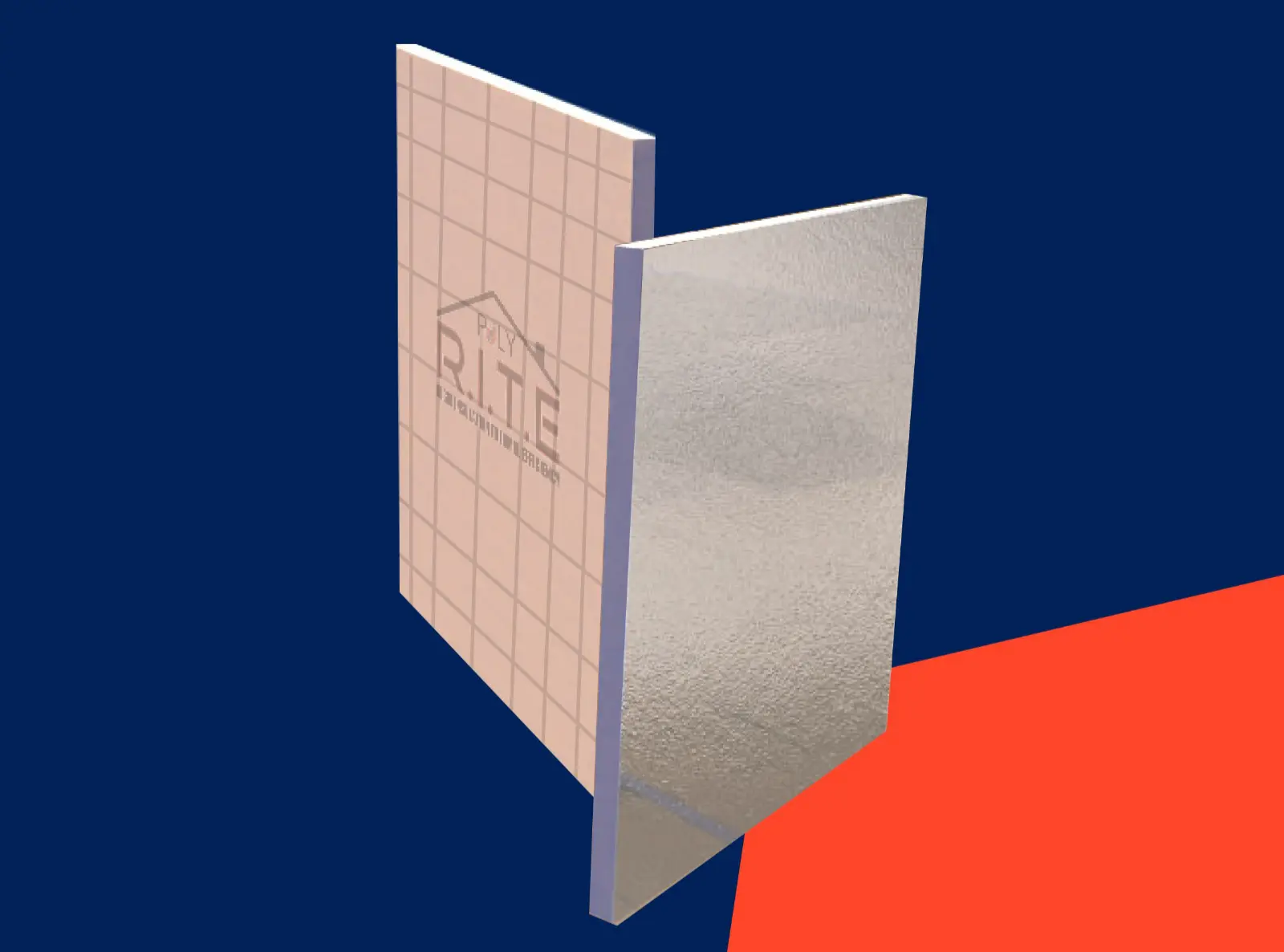

POLY R.I.T.E is an expanded polystyrene cored high density

laminated insulation board. The strength of POLY R.I.T.E provides a high standard of protection while also improving the insulation of your residential or commercial project.

This laminated sheathing board lays flat against the wall, is

exceptionally durable, lightweight, and is easy to install.

POLY R.I.T.E laminated insulation provides excellent R-Value and helps to conserve energy. It also resists moisture,

decreasing the risk of mold and mildew.

POLY R.I.T.E is available in densities from 25 psi to 60 psi. It

comes in standard 4’x8’ and 2’x8’ sheets with thicknesses

ranging from 3/8” to 2”.3

In the construction industry, achieving optimal structural integrity and thermal performance is paramount. Poly Molding’s EPS Flute Filler is a

When it comes to construction, the materials you choose can significantly impact project timelines, costs, and long-term outcomes. One of the most notable advancements in