Green construction projects are booming, with an increased demand for buildings and structures that are environmentally responsible and utilizes resources efficiently. It’s important to stay in touch with climate change and the ever-changing state of the environment. Here are some reasons why geofoam should be used in your next eco-friendly project.

Increased Energy Efficiency

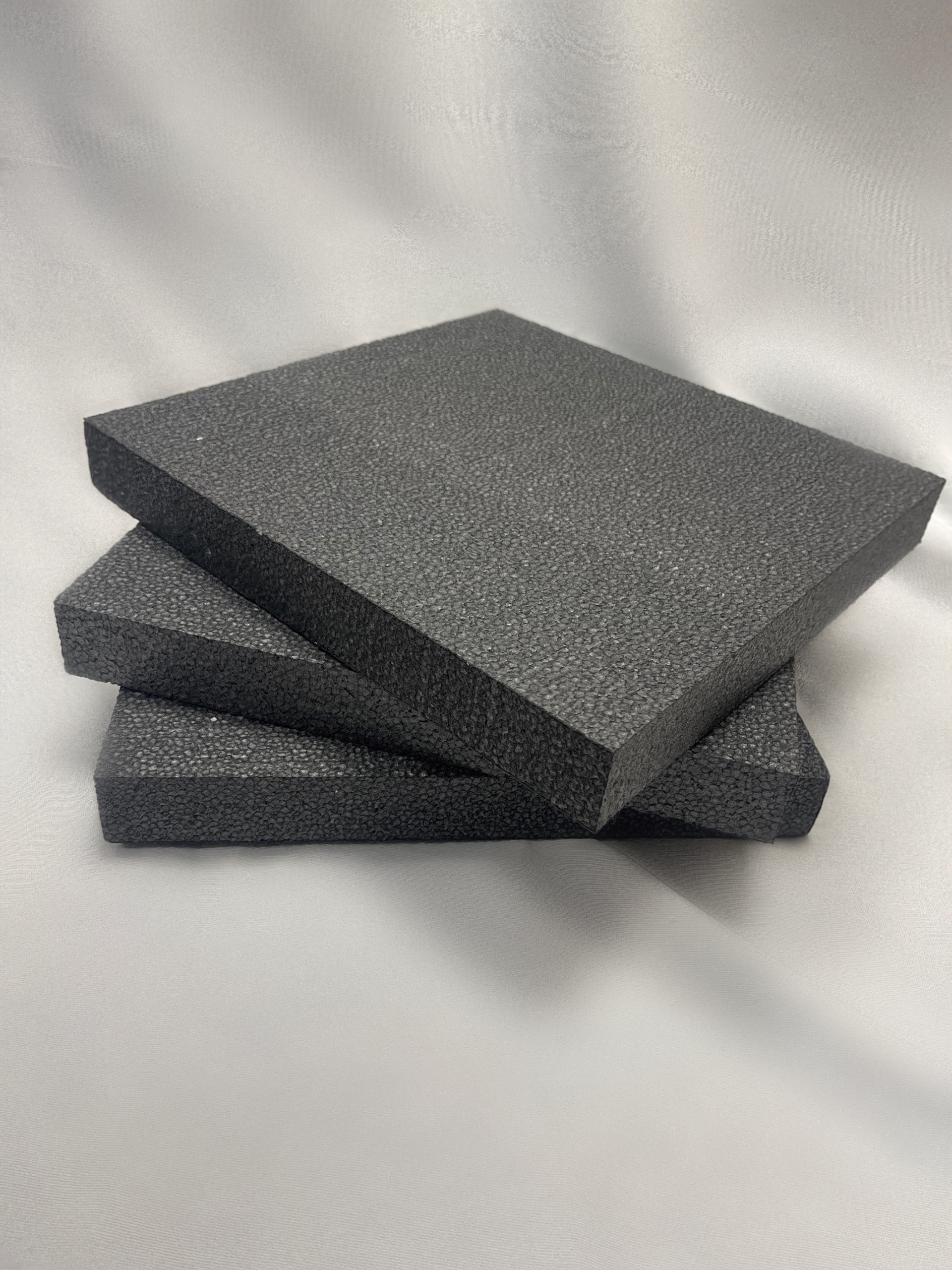

As the green construction industry flourishes, the demand for energy-efficient buildings is becoming widespread. In their aim towards LEEF certification, construction site managers are aiming to design the finest infrastructure with the smallest carbon footprint. Automated lighting, heating, and cooling systems, and smart house technologies are quickly becoming the new cornerstone for building development. Geofoam is increasingly being utilized to move towards the concept of sustainability, as well as to strengthen the foundation of energy efficiency. It is the preferred insulating material for projects like green roofs, pools, and general insulation. Geofoam aids in the reduction of energy loss as it is a lightweight and durable EPS material that serves as an effective thermal barrier, preventing internal and external air transfer.

Promotes Sustainability and Energy Conservation

Along with the rise in green construction comes the trend of engaging more sustainable and energy-conserving resources. Vegetative green roofs constructed with geofoam are one such example. Green roofs are completely or partially covered with plants grown on top of a waterproof membrane. In fact, some green roof designs include extra layers providing a root barrier, as well as a drainage and irrigation system. Geofoam has contributed to green roofing by assisting property owners and governments in developing planet-saving rooftop gardens that enhance air quality and produce for healthy living. Two other environmental advantages are stormwater management and temperature regulation. As for consumers, green roofs are good insulation, which lowers energy expenses and increases the roof’s lifespan, allowing them to save on replacement costs.

Withstands Extreme Weather Conditions

With climate change comes catastrophic weather conditions which have been occurring on a regular basis, wreaking havoc on both business and residential structures. Geofoam is being utilized more than ever before to construct structures that can withstand harsh and often unpredictable weather events like floods, earthquakes, and hurricanes. Insulated geofoam structures are much more resistant to emergency conditions as compared to stick-built structures. This material is also more resistant to strong winds and the detrimental effects of natural weather phenomenon. Furthermore, they are more resistant to earthquakes and fire as a result of the concrete structures they are built into.

Lessens Long-Term Environmental Impact

Geofoam blocks do not contain harmful dyes, formaldehyde, chlorofluorocarbons (CFCs), and hydrochlorofluorocarbons (HCFCs). They will also not leech into the ground in the long term. The geofoam manufacturing process does not use or release potentially hazardous greenhouse gases. The process also includes steam, and the water involved is always reused. Geofoam is also 100% recyclable and can be made with up to 10% recycled materials. Using it in a project in place of a naturally derived material like rock and wood ultimately helps with sustainability efforts.

Use Geofoam in Your Next Project with Poly Molding

Poly Molding is New Jersey’s only geofoam manufacturer specializing in top-quality geofoam products across different sectors and industries. If you would like more information about geofoam and how to incorporate it into your green construction project, contact us and our team of experienced professionals will be able to advise you accordingly.