Roof construction is one of the biggest and most significant disbursements that are made by owners of buildings. These important investments generally comprise of repair, maintenance, installation, insulation, a waterproofing membrane, and a roof deck. Designers of roof systems and contractors have been coming to the realization that roofing systems that make use of expanded polystyrene, which is also referred to as EPS, are capable of fulfilling building requirements that are highly demanding.

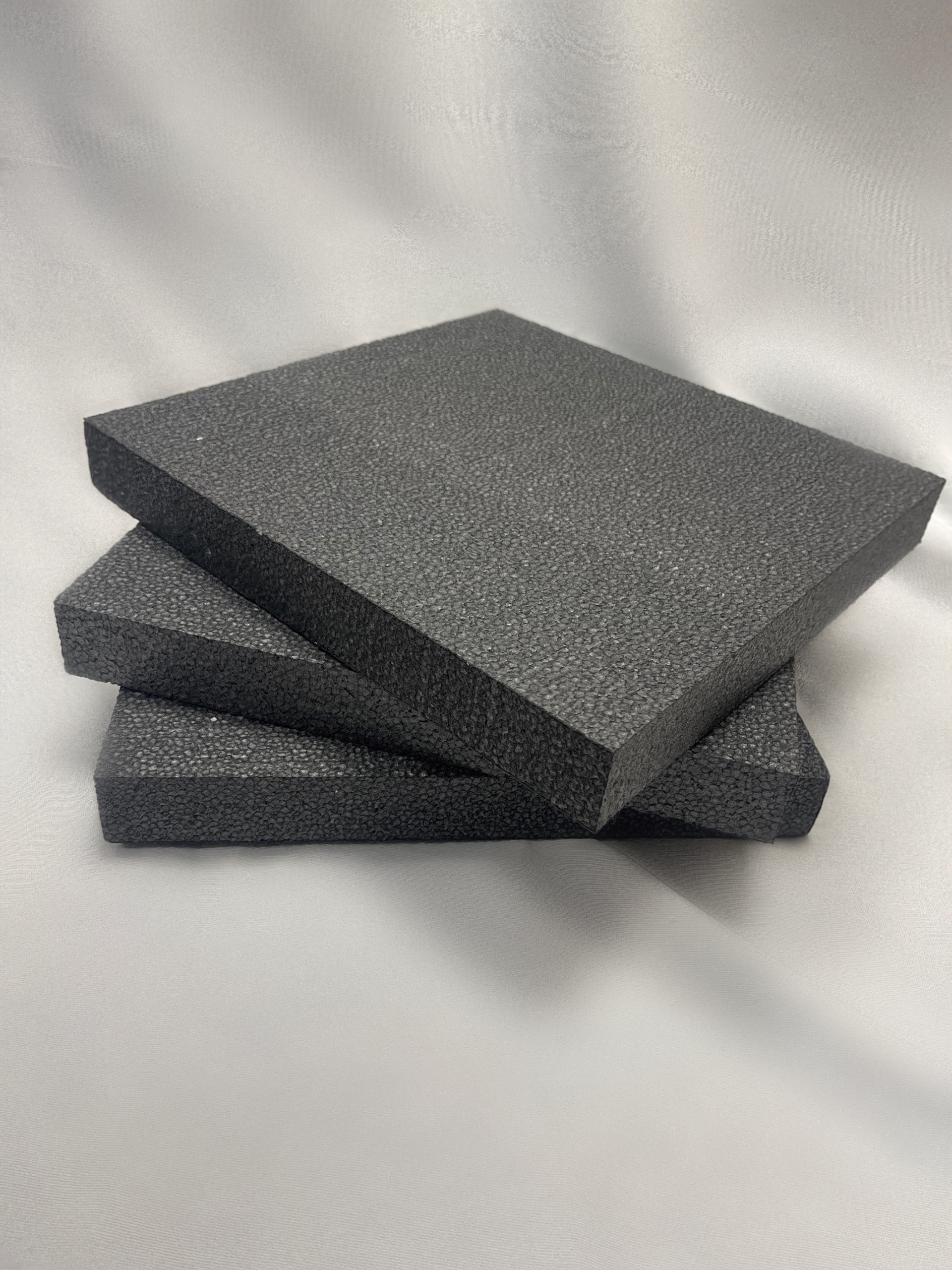

Expanded polystyrene is a resilient, lightweight, closed-cell insulation made of foamed plastic. It can offer dimensional stability, robust resistance to water, a long-term R-value, and substantial savings on energy expenditures when it is installed in a proper way and protected from the effects of moisture. Expanded polystyrene insulation is a good match with all the commercial roofing systems. Some examples of these expanded polystyrene-compatible roofing systems are modified bitumen, built-up roof, which is also referred to as BUR, and one-ply membrane systems that are fully adhered, mechanically fastened, or ballasted.

Applications of Expanded Polystyrene

Now, you might be wondering: what are the exact applications of expanded polystyrene, in terms of roof systems? Allow us to elaborate!

Tapered Roof Systems

Insulation for a tapered roof can assume an important role in the good and proper draining of roofing systems, which is highly essential to optimal levels of longevity and performance. The poor and improper drainage of commercial roofing systems can lead to damage that is much more severe than natural events such as strong winds or other types of natural phenomena. Freezing and thawing cycles, along with the ponding of water, have the potential to lead to expensive repair works and perhaps even the premature failure of a roofing system, which is very infrequently covered by insurance or under warranty. Tapered EPS insulation is capable of providing the positive slope that is needed while maintaining the economic and structural benefits that come with a roof deck with a low slope.

Built-Up Roof (BUR)

Expanded polystyrene has been consistently utilized in the applications of built-up roof systems for a period of over three decades. Built-up roof systems that are made with roof decks of concrete will allow for roof insulation to be directly applied to a deck. This is because there is not a need for a thermal barrier, which is due to the concrete deck that is not combustible. Expanded polystyrene foam can be joined to concrete with asphalt by using a technique that is referred to as the “mop and flop.”

Asphalt that has been heated to a high temperature is applied directly to the concrete deck, and it is then allowed to slightly cool, prior to the foam being permanently put in place. After this is done, a cover board is then “mopped and flopped” directly onto the expanded polystyrene insulation, with the joints taped and overlapping. Asphalt is then applied again on the top of the cover board, and this will provide a consistent and uniform base for the weatherproofing system.

Suitable Alternative

The current shortage in other insulating materials like Polyisocyanurate (poly-iso) insulation have made EPS a sustainable and efficient alternative.

Engineered EPS (Expanded Polystyrene) insulation is a suitable Poly-iso replacement. EPS provides several technical advantages over Poly-iso. Some contractors may claim that Poly-iso has a greater R-value, which is true when talking about published R-value, but Service R-value is a different story. Poly-iso’s R-value drops considerably as it ages, according to Long-Term Thermal Performance (LTTP). Further research has revealed that the R-value of Poly-iso falls when the temperature drops, which is when R-value is most needed. When it gets cold, EPS’s R-value changes only by increasing its effectiveness. This is only one of the many advantages of EPS vs Poly-iso.

Meet All Your Insulation Needs with Poly Molding

Poly Molding is New Jersey’s sole geofoam/EPS manufacturer and specializes in the supply and implementation of EPS products across different sectors and industries. Contact our team of experienced professionals if you are interested to find out more about Roofing insulation and how to incorporate it into your next project.