Metal roofing on residential and commercial structures is strengthened by using the ribbed profile to create adequate support for the roofing material. The space between the ribs is termed as flute, and the use of our Geofoam product as flute fillers close the gap between these spaces while making the roof moisture resistant and improving the R-Value of the roof assembly. One of the essential features of Geofoam as a flute filler is that it is very lightweight, inexpensive and strong.

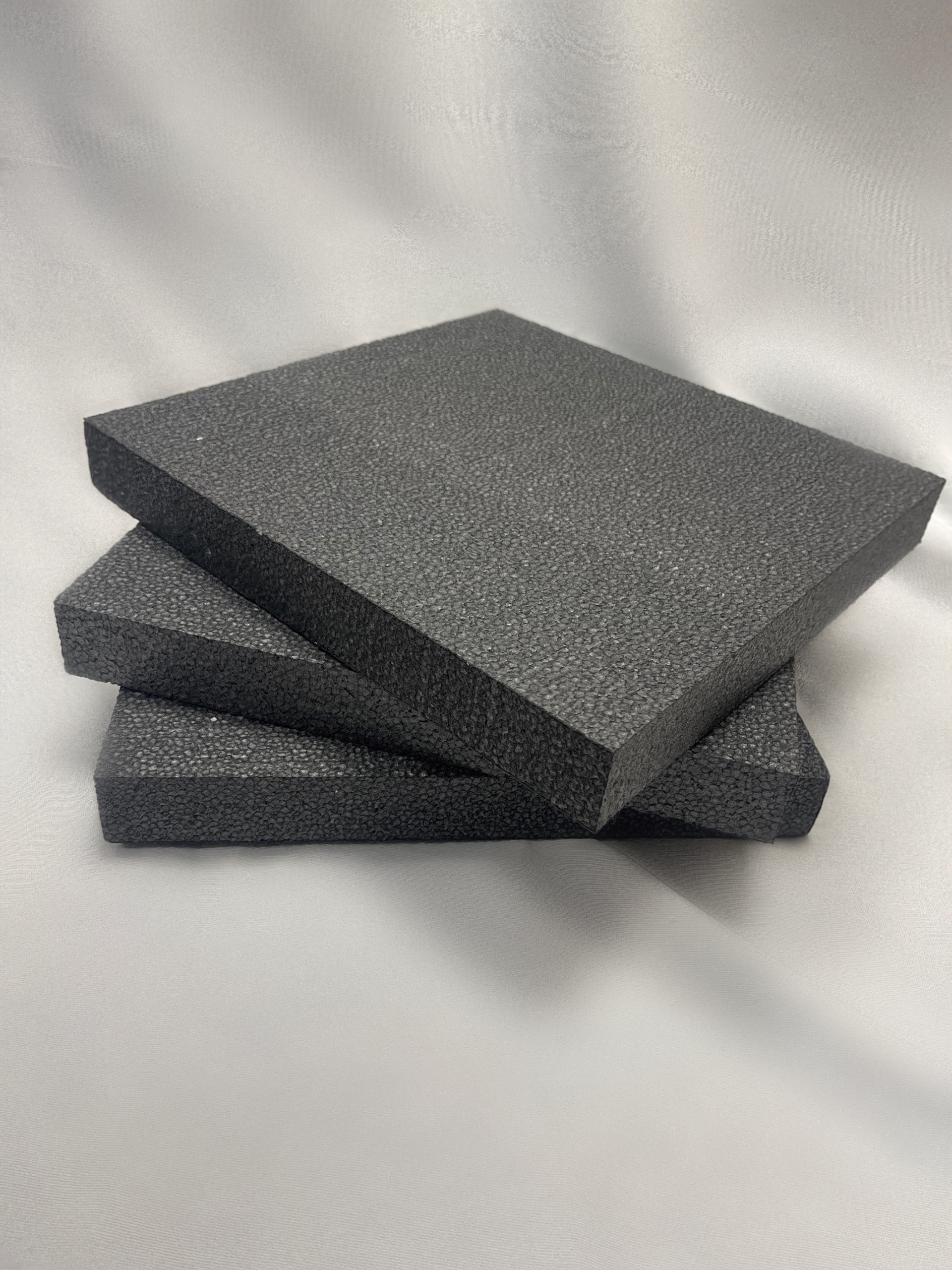

EPS Flute Fillers

Geofoam Expanded Polystyrene (or EPS) flute fillers are thermal resistant and durable pieces of insulation material that can be easily customized to match your roof profile meeting differing shapes and ribbed sizes. The ease of customization in flute fillers allows ribbed spacing to be fully covered without leaving any gap in between. Flute fillers usually come with a limited lifetime warranty which speaks for the durability and versatility of the product.

Benefits

- Lightweight Structure – Since they are made from expanded polystyrene, flute fillers are lightweight and can strengthen a surface without adding much weight to the whole structure.

- Versatility – Flute fillers, especially those that are manufactured using foam control technology, can be designed in different shapes and sizes allowing contractors to fit them into different types of ribbed profiles.

- Improve R-Value of your roofing assembly – Flute fillers like Geofoam improve the R-value of a surface, and for this reason, they are also used to support structures that need to withstand high pressure per square inch without adding much weight to the surface.

- Greater moisture resistance – The use of our geofoam products as flute fillers is the perfect marriage, as it does not absorb moisture from the surrounding air making the surface below the material last long without being exposed to dampness.

- Cost Effective – Once you have used a fluted filler on your roof or any other supporting structure, you do not need additional insulation material that could cost you significantly.

Commercial Uses of Flute Fillers

- Using Geofoam Flute Fillers To Strengthen Bridges – Flute fillers are also used to strengthen the bridge without adding much weight to the structure. The flute filler added in between the corrugated surfaces on the bridge deck allows for greater insulation and weighs less than the concrete filling.

- Flute Fillers For Deck Overhangs On The Wall – While the major purpose of a flute filler remains to strengthen the surface deck and keep it from absorbing moisture; on certain occasions, it is also used to fill the void between two reclining surfaces and create insulation to prevent dirt and insects from entering the structure. If a steel roof is extending the outer walls and creating voids between the roof ribbed and the wall surface, then small bits of flute fillers can be used to cover these voids to keep birds and small animals from entering the closed structure.

- Creating Insulation Between Two Walls – Commercial spaces are remodeled now and then as organizations enhance their operations. During such changes, Geofoam flute fillers are very effective when insulation and thermal break are required between the outer wall, and an additional partition is to make its way into the structure.

- Useful In Poor Soil Conditions – In certain areas where soil conditions are poor and not viable to support the base of the structure, flute fillers are used to fill in the void between grade beams and the soil below them; making a strong base for the structure to stand on.

Geofoam flute fillers are a great tool to add strength and enhance the life of a structure while maintaining the overall weight and remaining cost effective to the contractor. Their versatility makes them useful in many settings and can make them an important part of any construction process.