Safe and Durable

As EPS geofoam is waterproof and lightweight, it makes it a suitable choice for hilly roads or roads situated in areas prone to landslides. The objective for every road construction is to minimize the pressure on the hill, to prevent future landslides and slope collapse. By using EPS geofoam for roads, it is lightweight enough to lessen stress on the underlying soil while still being strong enough to support hillsides and allow roads to absorb the impacts of natural disasters. And to top it all off, EPS geofoam does not rot and degrade over a long period, ensuring long-lasting roads.

Quick Installation

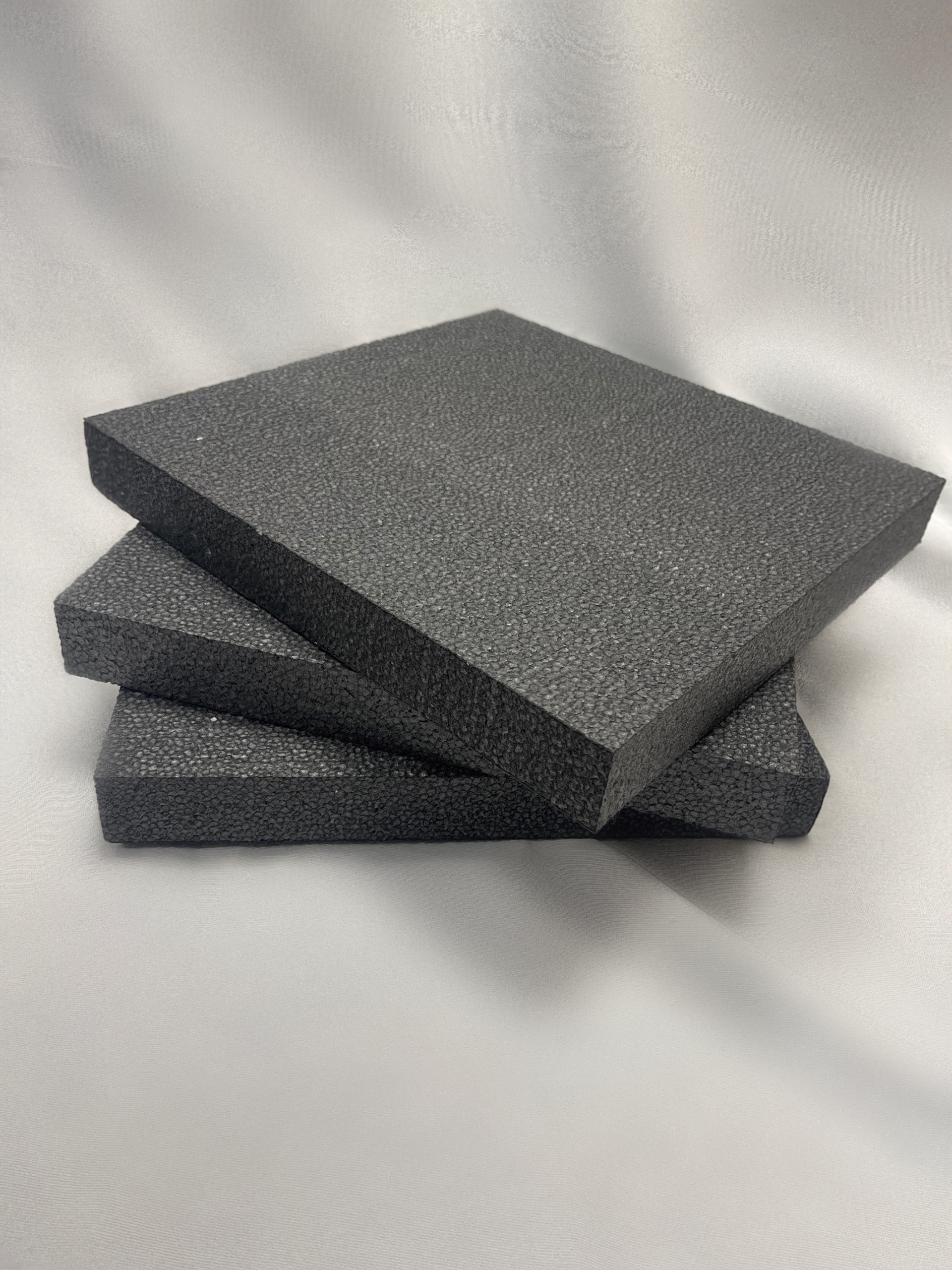

EPS geofoam significantly cuts down on installation time due to several factors. One of the factors is that since EPS geofoam is engineered and pre-cut in the factories, it does not require additional time for quality control and field trimming. The second factor is its light weight, which allows workers to easily lift the material and not depend on heavy equipment, hastening the construction process. A fun fact, EPS geofoam weights 100 times lighter than soil and 30 times lighter than traditional fill solutions.

Cost-Effective

It is estimated that a two-lane road in a rural area is priced between $2 to $3 million per mile, or $3 to $5 million per mile if the road is situated in an urban city. However, the price can add up due to many hidden costs throughout the construction process, such as transportation, weather conditions, and workplace risks. EPS geofoam removes these inconveniences as it does not require staging, preloading, and a large amount of manpower, thus preventing any added expense.

Suitable for Vulnerable Soil

Being lightweight, EPS geofoam makes for a great fill material for construction projects, especially for highways that experience frequent and heavy traffic loads. It is also highly resistant to high compression, which is why many construction firms opt for EPS geofoam to build roads situated on soil that is too loose and soft to provide a sturdier foundation.

Why Choose Poly Molding?

Aside from being the sole EPS geofoam manufacturer in the whole of New Jersey, we also provide the highest quality of geofoam products that are not only affordable but also long-lasting. In fact, our products have been used in the rebuilding of Hurricane Sandy and 9/11. While we’re based in New Jersey, we have serviced many construction projects throughout the Northeast coast of the United States, from Massachusetts to Delaware.